You are here:

Pollution Prevention (P2) and TRI

TRI's P2 Search Tool now helps you identify P2 successes and visually compare P2 performance at both the facility and corporate level. Find out more by watching our recent webinar or looking through the presentation slides.

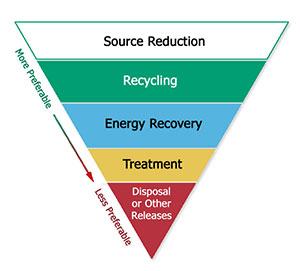

The Waste Management Hierarchy

The PPA calls for pollution to be prevented or reduced at the source whenever feasible and released to the environment only as a last resort.

- Learn about these terms

- Source Reduction includes activities that eliminate or reduce the generation of chemical waste.

- Recycling includes the recovery of a toxic chemical in waste for reuse.

- Energy Recovery includes the combustion of toxic chemicals in waste to generate heat or electricity.

- Treatment includes the destruction of a toxic chemical in waste.

- Disposal or Other Releases includes toxic chemical quantities entering the environment.

Under the Pollution Prevention Act of 1990 (PPA), TRI collects information to track industry progress in reducing waste generation and moving towards safer waste management alternatives.

When providing this information, many facilities choose to describe the measures they have taken to prevent pollution and reduce the amount of toxic chemicals entering the environment. As a result, TRI serves as a tool for identifying effective environmental practices and highlighting pollution prevention successes.

Access TRI's P2 Data

- Use TRI Search to find P2 data for a specific facility

- Use P2 Search to get info by sector, chemical or parent company, and compare P2 progress

- See how P2 is featured in the TRI National Analysis

- Download all P2 data for 2013, 2012, or 2011 (Excel)

- Learn about specific P2 accomplishments in our P2 Spotlight series

Learn About Reporting P2 to TRI

- Download the TRI P2 Reporting Tip Sheet (PDF)

- View the TRI P2 training webinar for facilities,

Showcasing Sustainability in Your TRI Report

Other TRI P2 Resources

- Learn about TRI P2 data and how to use it (PDF)

- View the TRI P2 training webinar for data users,

Exploring TRI's Pollution Prevention Information Exit - Learn more about EPA's P2 and sustainability programs

Source Reduction Activities Reported to TRI

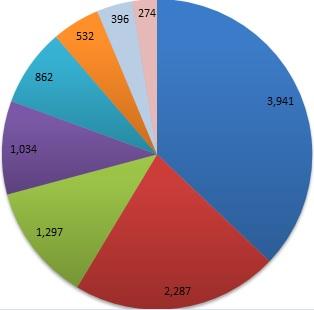

For 2013, a total of 3,362 facilities (16% of all TRI facilities) reported initiating 10,623 source reduction activities. Good operating practices, process modifications, and spill and leak prevention were the activities reported most frequently.

Number of Activities Reported, 2013

To see examples of source reduction activities reported by TRI facilities, click on the color-coded legend next to the pie chart.

Good Operating Practices (3,941)

Good Operating Practices (3,941)

Good Operating Practices

Examples:

- An industrial gas manufacturer increased the frequency of its planned maintenance, with a focus on packing and gasket materials. This resulted in decreased emissions and a decreased use of raw materials.

- The production scheduler and production supervisor at an organic chemicals manufacturer continuously adjust the batch schedule to minimize product changes, which reduces waste from cleanouts.

- A transformer manufacturing facility reduced overall operator-controlled scrap through a technical hands-on training, funded by a grant from North Carolina. This yielded a 50% overall reduction in operator-controlled scrap.

Process Modifications (2,287)

Process Modifications (2,287)

Process Modifications

Examples:

- To reduce the amount of solvent used, a plastics product manufacturer modified the facility’s process to allow for an additional cycle of trichloroethylene distillation and use prior to disposal. The change was made in 2011, and from 2010 to 2012, the facility’s trichloroethylene releases declined by 71%.

- A commercial printer added a more efficient and automated solvent still to improve its recovery of solvents and also installed a more efficient printing press. From 2011 to 2012, the facility reduced its methyl isobutyl ketone waste by 20% while production increased by 15%.

- One electric generating facility reduced the amount of ammonia used in its selective catalytic reactor to control nitrogen oxides (NOx) emissions by optimizing reaction conditions and replacing ammonia injection control valves.

Spill and Leak Prevention (1,297)

Spill and Leak Prevention (1,297)

Spill and Leak Prevention

Examples:

- An organic chemical manufacturer implemented a new policy to reduce spills due to hose failure. This policy requires the electronic identification and annual testing of all hoses that are used to transfer chemicals.

- A coke plant rebuilt 23 coke ovens and implemented numerous end-flu repairs to reduce the amount of leaks in the ovens. This reduced the facility’s total stack emissions in 2012.

Raw Material Modifications (1,034)

Raw Material Modifications (1,034)

Raw Material Modifications

Examples:

- A distillery reduced its use of coal for generating steam and relied more on its natural gas boiler instead. This change corresponded with a 30% decrease in the generation of hydrochloric acid aerosols from 2011 to 2012 and reduced greenhouse gas emissions even though production increased.

- A motor vehicle seating and trim facility is largely eliminating the use of a high xylene content material, except for minor use in service parts manufacturing. Two key technology changes that enabled this change are the use of flame and plasma surface treatments and better formulations of water-based painting technologies. Total disposal or other releases of xylene at this facility fell by 30% between 2011 and 2012, and reductions are expected to continue in 2013.

- A paper mill installed a new power boiler to generate steam from natural gas rather than coal. Total disposal or other releases of barium compounds from this facility fell by over 40% between 2011 and 2012, even though production associated with barium compounds rose slightly in the same time frame.

Product Modifications (532)

Product Modifications (532)

Product Modifications

Examples:

- A brass and aluminum casting facility is working with customers to replace its current alloy, which has a maximum 6% lead, with a new alloy that has a maximum of 0.09% lead. The facility reports that customers are looking for low-lead or lead free alternative alloys, including national water works associations which require less lead in materials that contact drinking water.

- A disinfectant products manufacturer is phasing out a cleaning product that uses 2-phenylphenol (OPP) as a reactant and has developed new products that do not use OPP. This has resulted in a large reduction in offsite disposal of this chemical.

- A fiberglass building insulation manufacturer tested a new resin with lower formaldehyde content for one of its production lines in 2012 and 2013. The facility is working on formally implementing the change.

Inventory Control (862)

Inventory Control (862)

Inventory Control

Examples:

- A communications equipment manufacturer improved inventory scheduling and reduced the quantity of expired products of which it must dispose. This facility also reclaims lead off-site from solder dross and uses on-site administrative controls to maximize the usage of lead solder.

- Through participative team management, a meat processing facility identified a change in inventory control where the sodium nitrite inventory is carefully controlled using premeasured amounts in small quantity bags.

Cleaning and Degreasing (396)

Cleaning and Degreasing (396)

Cleaning and Degreasing

Examples:

- Based on an employee recommendation, a fabricated metals facility decommissioned its dichloromethane degreaser in 2012 after purchasing a new parts washer that uses hydrocarbons. This change will entirely eliminate the facility’s use of dichloromethane.

- An aircraft manufacturer substituted an alkaline cleaning process for some of its tetrachloroethylene degreasing in 2011. Its tetrachloroethylene releases and production-related waste managed declined by about 30% from 2010 (prior to the change) to 2012, even though production increased by more than 30% during this time period.

Surface Preparation and Finishing (274)

Surface Preparation and Finishing (274)

Surface Preparation and Finishing

Examples:

- The engineering team at a coated and laminated paper manufacturing facility has identified a new adhesive coating technique that drastically reduces the need for their main diluent solvent.

- A farm machinery and equipment manufacturer is in the process of replacing their current paint system with a powder booth, which will begin production in 2014. They expect that releases of 1,2,4-trimethylbenzene will drop below reporting threshold.