Additive Manufacturing

Additive manufacturing, more commonly known as 3D printing, is a process used to generate a physical model from a digital computer model. The model is "sliced" into thin layers by the printer software, and each layer is successively built up. Several different 3D printing technologies exist, with many different material options available. Each machine and material has unique properties that should be considered when choosing a process.

3D printers require an STL file, which can be generated using one of many different software programs. Solid models (instead of surface models) are generally used to generate appropriate STL files.

The PRL has two 3D printers available for student use, both of which are located in Room 36 in the Huang Engineering Center. 3D printing in the PRL has been used to build mechanical prototypes for testing, tooling for silicone molding and sand casting, and as artistic or decorative pieces. Students are required to pay for material costs before builds begin.

Machine Specifications

| Dimension 1200es BTS | Ultimaker II | 3D Systems ProJet 3500 HD | |

|---|---|---|---|

| Additive manufacturing technology | FDM (Fused Deposition Modeling) Plastic filament and support materials are pushed through heated extrusion tips that trace each cross-sectional layer. Build time is approximately linear with the increase in cross-sectional area. |

Similar to Dimension 1200es BTS machine | MJM (Multi-Jet Modeling) Plastic material and wax support materials are melted and jetted across each cross-sectional layer of geometry. Intermittent UV flashes ensure even part curing. Build time is determined by the height of the tallest part. Building multiple copies of a given part does not increase build time. |

| Layer Resolution | 0.010" 0.013" |

0.06mm - 0.25mm | 32u (HD mode) 29u (UHD mode) |

| Build volume (xyz) | 10" x 10" x 12" | 8.7" x 8.7" x 8" | 11.75” x 7.3” x 8” (HD mode) 5” x 7” x 6” (UHD mode) |

| Material | ABSplus part material, breakaway ABS support material | PLA/PHA blend | VisiJet Crystal part material (acrylic-like), wax support material |

| Operation in the PRL | Reservable on Webshop, requires completion of self-guided tutorial on the machine | Reservable on Webshop, requires completion of self-guided tutorial on the machine | Build packs are created by the lab manager. SUBMIT REQUEST Please note, ProJet use for research purposes is not allowed. Please see below for alternative resources better suited to researchers. |

| Best option for: | -Structural parts with wall thicknesses over approximately 0.080” -Bulky parts that can benefit from decreased build cost using a sparsely-filled model |

-Quick prototypes where surface imperfections are acceptable -Bulky parts that can benefit from decreased build cost using a sparsely-filled model |

-Small, precise parts -Parts with holes or complex internal geometry -Parts that are built as moving assemblies |

Instructions for Use

To use the FDM or Ultimaker II, you need to complete the respective self-guided tutorials on the machine. A reservation on WebShop is helpful to ensure that the machine will be available. Take a look at the tutorial documents for the FDM or Ultimaker before coming into Room 36 to use either machine.

ProJet builds are coordinated by the lab manager. SUBMIT REQUEST

You will receive a price quote by email, generally between 9am-5pm on weekdays. To confirm a build, visit Room 36 during an open session to pay the TA on duty. Be sure to have the TA sign off on your build form when you have paid.

IMPORTANT

Job size limitations: The ProJet is great for small, high-precision parts. Jobs exceeding the following parameters cannot be printed:

*Combined Support/Model Mass: .5kg (1.1lb)

*Part Volume: 175,000 mm^3 (~10.5 in^3)

*Print Time: 24h

*Maximum z-height: 100mm (~4")

After the build is complete, the plastic parts will need to be removed from the build platform and post-processed to remove the wax support material. This process can take an hour or more, so budget accordingly.

ProJet part Post-Processing instructions.pdf

Tech Notes

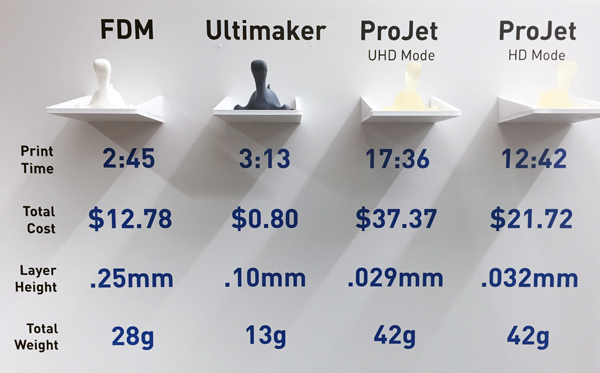

The three machines each have different layer thickness options, and the FDM has a variable density setting. Compare estimated build time and cost between the FDM and ProJet: FDM and ProJet cost and build time comparison.pdf. Come by Room 36 to look at the same file created with each of the three machines and get a better feel for their capabilities:

To create moving assemblies on the ProJet, create a gap of at least 0.005" between adjacent components. For example, a pin of diameter 0.125" should be centered in a hole of 0.135" diameter to ensure that the wax can be melted out from between the components. If your fit is very critical, we always suggest printing a test part to verify your geometry.

Fictiv has excellent resources for designing and finishing printed parts - for example:

*The ultimate guide to finishing 3D printed parts

*How to spray paint 3D models

*Designing snap fit components

*How to choose the best fasteners for 3D printed parts

Alternative Additive Manufacturing Resources

The Product Realization Lab is a teaching laboratory and we find the research demand for us to print parts decreases our ability to fulfill our primary teaching mission. There is an alternative service organization on campus whose purpose is to fill this need, and there are numerous local and web-based services that can be used as well.

Additional Additive Manufacturing Resources:

If your additive manufacturing needs exceed the bandwidth of the Product Realization Lab, here are a few alternatives you might look into. Please remember that it is your responsibility to determine if a vendor, material, build process, and lead time are appropriate and will meet your needs.

On campus:

* Garner Lab in Comparative Medicine. Connect through iLab. One of the big benefits to using this service is that they are part of the university system and payment for builds can be made directly with a PTA account.

Local:

*ProtoCafe

*Studio Fathom

Web-based: There are many web-based services that provide additive manufacturing services, using many different processes and materials.

*Fictiv

*i.Materialise

*Quickparts

*Shapeways (They offer a 10% educational discount)

*3D Hubs

*ProtoLabs