Formally Accounting for Variability in Look-ahead Planning

Project Team

M. Fischer, R. Levitt, N. Garcia-Lopez

Overview

Field managers lack a method for analyzing the impact of workflow variability on activity execution and understanding how variability is propagated between activities. As a result, they cannot anticipate the impact of workflow variability and rely on their experience and intuition managing workflow variability during look-ahead planning. I propose to formalize the Activity Variability Method (AVM), which uses a model representing construction activities and the flows connecting the activities, to analyze the in-project workflow variability and predict its impact on downstream activities. Using the AVM, field managers can identify targeted strategies to shield activities from workflow variability. The model for representing construction workflow, including the activities, flows between the activities, and the mechanisms causing workflow variability, will be developed from literature and validated with available variability tracking data from three projects. The AVM will be developed based on the application of the Last Planner System and input from field managers. The AVM will be validated by testing its implementation on a construction project.

Project Background

Research Motivation

Despite recent advances in the use of Building Information Modeling (BIM), lean approaches, and information technology systems, construction projects still continue to face problems managing on-site construction resulting in schedule and cost overruns (Jones and Bernstein 2014). In manufacturing, companies have achieved exceptional performance by systematically seeking to understand and manage variability (Womack and Jones 1996). Recently, construction researchers have revealed the negative impact that workflow variability has on construction performance such as: higher work in process, longer activity durations, and project completion delays (Arashpour and Arashpour 2015; Tommelein et al. 1999). However, there have been limited efforts developing methods that aid field managers to anticipate and manage workflow variability in the field.

This need motivated us to submit a Seed Proposal in 2014. We proposed to develop a simulation model to help field managers understand the impact of implementing different production management strategies on the production system metrics (time and cost). However, the findings from the initial case studies and a deeper exploration of the existing literature drove us to shift our focus. We found that field managers lacked a method that helped them understand the causes of workflow variability, and its impact on downstream activities. Hence, they were unable to anticipate the impact of workflow variability and implement targeted management actions to shield the activities. This motivated us to refocus the research and develop a method that uses the activity tracking data resulting from the Last Planner commitment tracking phase, namely the planned versus actual data for activity completion and the reasons for variance, together with the look-ahead schedule to predict the impact of workflow variability on downstream activities. Using these predictions, field managers can implement targeted measures to reduce the impact of variability on activity execution.

Observed Problem

Field managers lack methods to anticipate the impact of variability on downstream activities. As a result, they cannot formally manage workflow variability and rely on their intuition and past experience implementing measures to shield downstream activities from upstream variability.

Research Objectives

1. To understand what variability factors affect what construction flows.

2. To understand how variability in the construction flows causes variability in the activities.

3. To understand how field managers can and should measure the variability factors, construction flows, and activity execution.

4. To develop a computational model that allows field managers to predict how variability is propagated to downstream activities.

5. To understand how field managers can use the computational model to manage variability and its impact during look-ahead planning.

Research Findings

Case Study Analysis:

We carried out two case studies to understand how field managers at construction sites manage workflow variability during look-ahead and commitment planning. We attended all scheduling and planning related meetings at the projects during a two month period.

Findings:

- Field managers lack formal methods for managing variability and estimating its impact.

- Field managers rely on their intuition and past experience managing variability.

Analysis of activity variability data

We analyzed the activity tracking record of a building project that had implemented the Last Planner System. The data set consisted of 30,000 activity entries. We carried out a manual cleanup of the data, expanding the data set to include: activity classification (activity type and UNIFORMAT), and subcontractor type.

Findings:

- Activity total variability is skewed to the right: median = 0, mean = 2.26 days. This means that it is more likely that an activity will finish late than early.

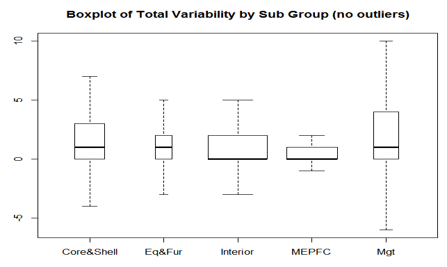

- Management activities have higher variability than other activities. MEP activities have lower variability than other activities.

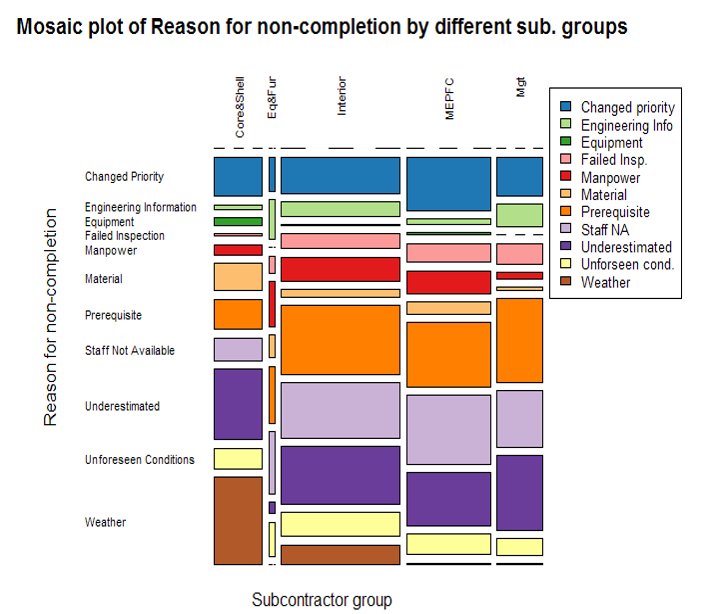

- The relative importance of different reasons for non-completion varies by subcontractor group

- We were unable to identify any clear clusters of activities according to their variability level by classifying them by Subcontractor type, UNIFORMAT classification, or activity type.

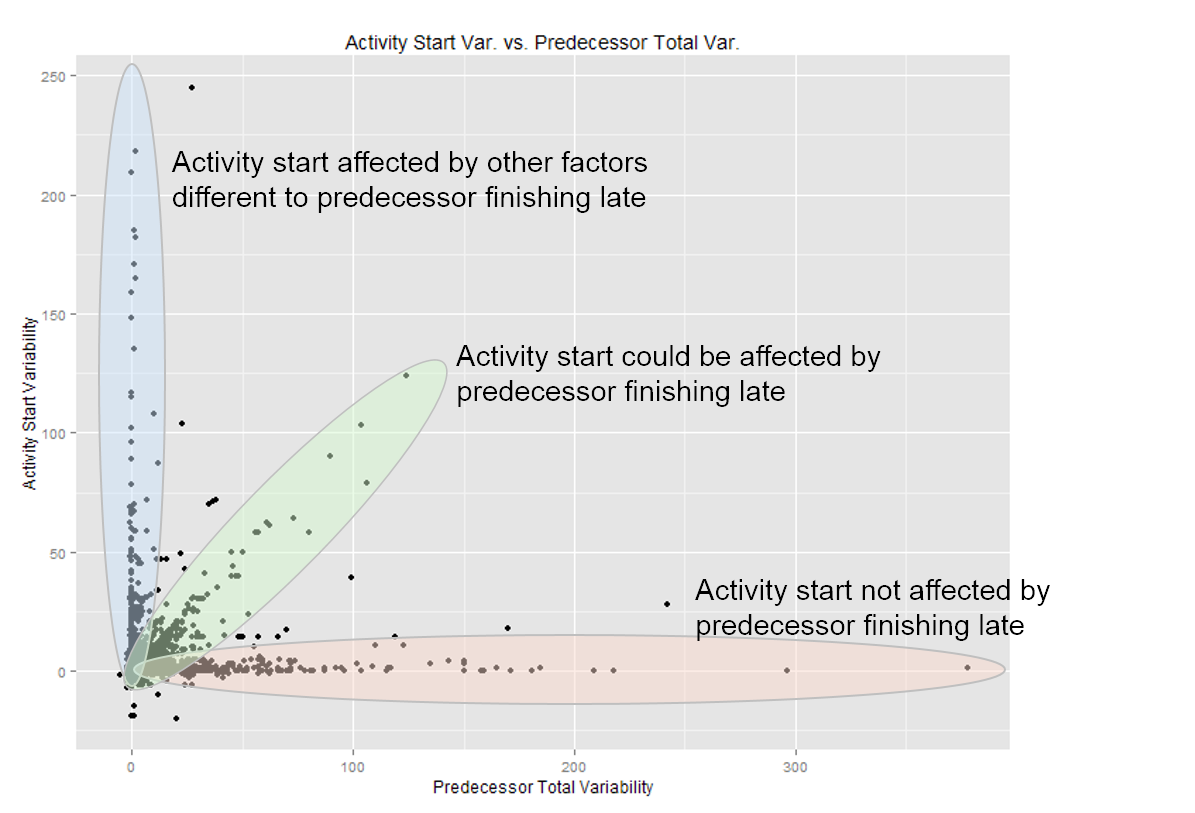

- There is a strong relationship between the activity having a positive start variability (starting late) and the predecessor activity finishing late.

Research Proposals

CIFE Seed Proposal 2015:

CIFE Seed Proposal 2014:

Last modified Wed, 19 Aug, 2015 at 10:46